OPTIBAR DP 7060

Differential pressure transmitter for flow, level, differential pressure, density and interface measurements

- High performance DP transmitter with integrated line pressure measurement

- Measuring range: 30 mbar…16bar / 0.44…232 psi; Line pressure: up to 400 bar / 5800 psi

- Reference accuracy of ±0.065%

- 2-wire, 4…20 mA/HART®, FF, Profibus-PA, Bluetooth®

OPTIBAR DP 7060

The OPTIBAR DP 7060 is a differential pressure transmitter with integrated absolute pressure measurement. It offers a high degree of modularity for various flow, hydrostatic level or process pressure applications. For DP flow measurements it can be perfectly combined with the KROHNE primary elements (e.g. orifice plates or pitot tubes). Equipped with diaphragm seals, it is the right choice for hydrostatic level, interface, density or demanding DP process applications. Featuring a quick response time of just 125 ms, the DP transmitter offers high accuracy and measurement stability under all process conditions.

KROHNE is the only manufacturer of process instrumentation to carry out a total 3D linearisation of its differential pressure transmitter. For a robust and accurate differential pressure measurement, even under changing process conditions, each OPTIBAR DP 7060 differential pressure transmitter is linearised in all three dimensions during calibration: differential pressure, ambient temperature and static pressure are taken into account in combination. Since the full specified operating range is covered, an utmost stable and accurate measurement under all process conditions is guaranteed.

Product highlights

- Outstanding temperature and static pressure stability even under harsh conditions

- Unique 3D linearisation of transmitter: compensation for all influencing factors at virtually all possible combinations

- Very good repeatability and long-term stability of the measuring signal

- Integrated absolute pressure measurement for lowest possible influence of static pressure changes on the signal while providing an additional process signal

- Very quick step response times <125 ms

- Combined DP, SP and T measurements for maximum process security

- Compact measuring cell with low weight

- Turndown ratio up to 100:1, higher upon request

- Extensive diagnostic and parameterization functions on the display and adjustment module or the user-friendly and free DTMs

- Wireless device commissioning, verification and monitoring with the OPTICHECK Pressure Mobile app

- Ex ia, Ex d approvals

- SIL 2/3

Typical applications

Chemical, petrochemical, power generation, food and beverage, water and other industries

- Pressure monitoring of filters and pumps with overload protection of up to 160 bar / 2320 psi

- Level measurement of liquids in pressurized vessels

- Flow measurement of gases, vapours and liquids with primary elements

- Measurement of density and separating layers of liquids in tanks

Accessories for this product

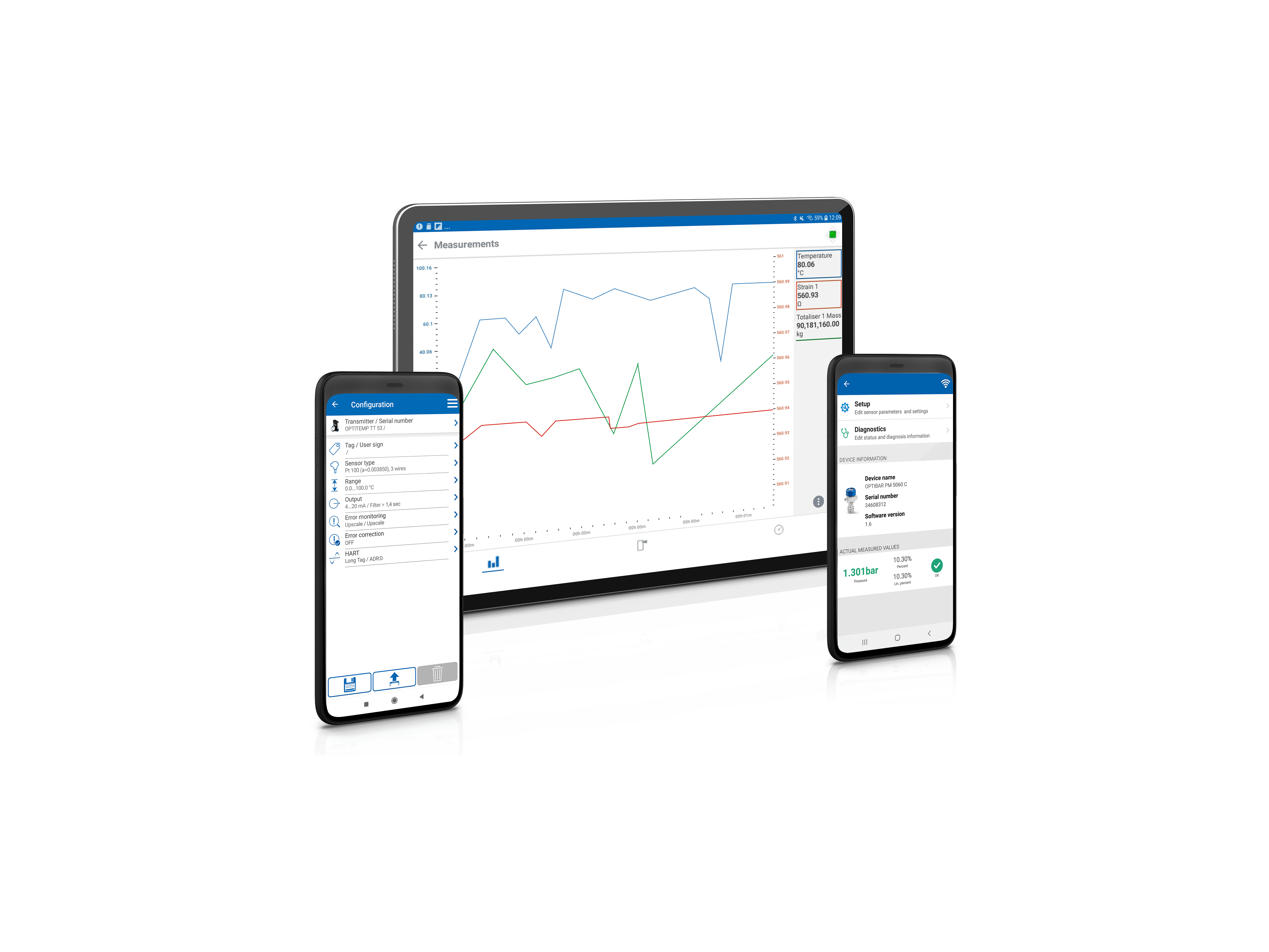

OPTICHECK Mobile

Mobile app for wireless device commissioning, verification and monitoring

- Wireless commissioning and device parametrisation via secure Bluetooth connection

- Verification without measurement interruption

- Monitoring of meter performance and application parameters

- Free download for iOS and Android

Applications

Related products

Download Center

Pressure instruments

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver