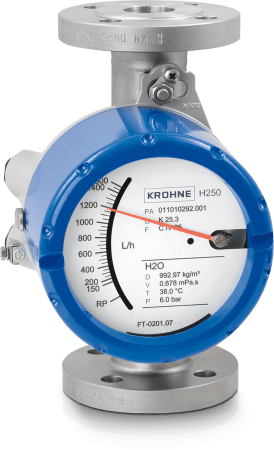

H250 M40

Variable area flowmeter for liquids and gases

- Modular design: from mechanical indicator to 4…20 mA/HART®7, FF, Profibus-PA and totalizer

- Any installation position: vertical, horizontal or in fall pipes

- Flange: DN15…150 / ½…6"; also NPT, G, hygienic connections, etc.

- -196…+400°C / -320…+752°F; max. 1000 barg / 14500 psig

H250 M40 – Standard version with flange

The H250 M40 is the standard variable area (VA) flowmeter for the process and OEM industry. The VA meter combines mechanical flow measurement of liquids or gases with state-of-the-art communication capabilities. The device is modularly extendable. Additional electronic modules can be added or replaced at any time without process interruption. In this way, its functionality adapts to new requirements – from analogue flow measurement without auxiliary power to digital integration into a fieldbus system.

The H250 M40 is available in various materials and in many different versions. The sturdy all-metal flowmeter can be also used in applications with high pressures (up to 1000 barg / 14500 psig), temperatures (-196…+400°C / -320…+752°F) or aggressive media. It even allows installation in horizontal or fall pipes up to DN150 / 6". A special version for use in hygienic applications is also available. The H250 M40 is intrinsically safe and explosion-proof. Certain variants of the flowmeter with limit switch or analogue output are suitable for use in Safety Instrumented Systems (SIS). Electronic device diagnostics and additional application diagnostics are available to increase application reliability, e.g. the detection of a float blockage due to impurities or pressure surges and the reporting of pulsating flow or gas compression oscillations of the float.

Product highlights

- Simple, low-cost installation: able to measure and display without auxiliary power supply

- Unique modularity and serviceability: Limit switches, 2-wire 4…20mA, totalizer with LCD and pulse output, fieldbus interfaces

- NE 107 device and application diagnostics with CFM (Continuous Float Monitoring), e.g. for float blockade detection

- Universal ex-concept: Explosion proof and intrinsically safe

- Various stainless steel and alloy sensor materials

- Optional stainless steel housing for corrosive atmospheres

- Ingress protection IP66 and IP68 / NEMA4X and NEMA6, IP69K optional

- Full scale value for liquids: 10…120,000 l/h / 5…32,000 GPH

- Full scale value for gases: 0.7…2800 m3/h / 25…100,000 SCFH

- Turndown ratio 10:1 (optional 100:1)

- Maximum measuring error: ±1.6% (acc. to VDI/VDE 3513-2) or ±1.5% of full scale

- Suitable for use in Safety Instrumented Systems with SIL 2, in redundant design (1oo2) also in SIL 3 applications (type A device)

- Optional hygienic design for use in the food and pharmaceutical industry

Typical applications

Chemical and other process industries

- Additives (e.g. catalysts, tensides, foam inhibitors, emulsifiers)

- Acids, bases, phosgene and other chloridic substances, sulphuric substances

- Condensate and cooling water

- Nitrogen inertisation of vessels and tanks

- Sample flow monitoring for process analysis

- Gas sparging in liquids

Oil and gas industry

- Injection skids for corrosion-, scale- and hydrate-inhibitors

- Nitrogen, flue gases etc.

- Emulsifiers

Machinery and apparatus (OEM industry)

- Gas seal monitoring for compressors

- Coolants and cooling water, lubricants, air supply

- Dry-run prevention of pumps

- Gas and oil measurement for industrial furnaces

Pharmaceutical industry

- Demineralised water, alcohol, solvents, insulin etc.

- Cleaning agents

- Air measurement in clean rooms

Food and beverage industry

- Vegetable oil, drinking water, milk, carbon dioxide

- Cleaning agents

Water and wastewater industry

- Oxygen sparging into aeration basins

- Air injection to reduce iron content

Conventional and nuclear power industry

- Heavy water, borated water, tritium etc.

- Hydrazine

- Sulphuric acid

- Phosphate, nitrogen, hydrogen, sulphur

- Purified water, saline water etc.

- Steam, air, gases, boiler washing water etc.

- Diesel, return fuel oil flows etc.

Product variants

H250 M40

Standard

Variable area flowmeter for all standard applications with gases and liquids

- Modular electronic design for upgrade and replacement on site

- Globally approved for use in hazardous areas for globally acting chemical end users and OEM

- SIL 2 conform acc. to IEC 61508-2

- Flanged, threaded, clamp or welding connections

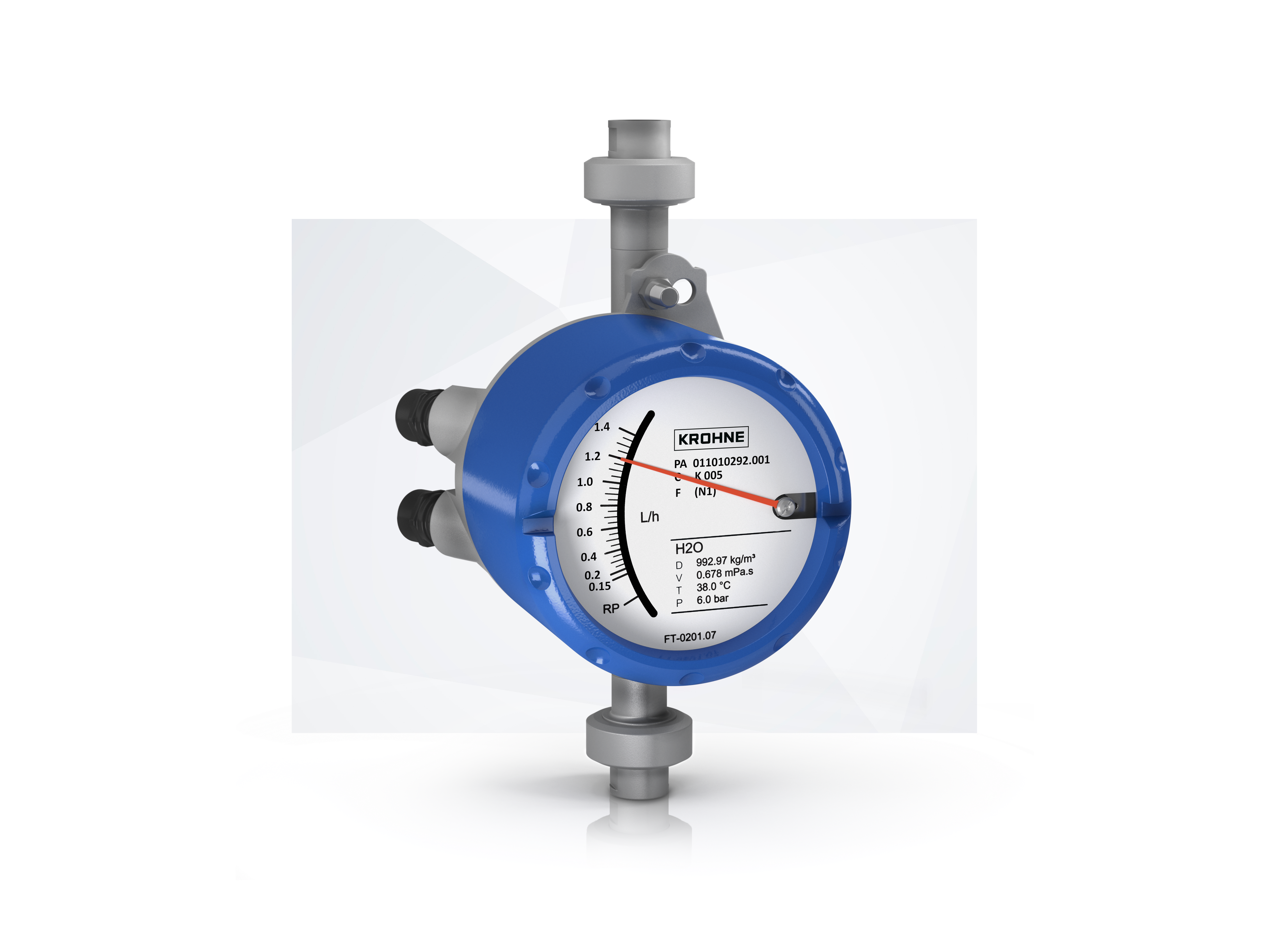

H250 M40 Low Flow

Variable area flowmeter for low flow applications

- Unique design for low flow rates

- Full scale value down to 1.5 l/h / 0.04 GPH (liquids) or 16 Nl/h / 0.6 SCFH (gases)

- Modular electronic design for upgrade and replacement on site

- Globally approved for use in hazardous areas for globally acting chemical end users and OEM

H250F M40

Variable area flowmeter for food and beverage applications

- Hygienic stainless steel design without dead spaces and stagnation zones

- Hygienic clamp, threaded or flanged connections

- Surface roughness: Ra<0.8 (optional 0.6)

- For use with SIP and CIP agents up to +200°C / +392°F

H250C M40

Variable area flowmeter for aggressive acids and bases

- With wetted components made of PTFE or ceramics

- Accuracy: ±2.5% (acc. to VDI/VDE 3513, sheet 2)

- Up to +250°C / +482°F (with TFM /ceramics)

- Liquids up to 60 m3/h / 15850 GPH; Gases up to 350 Nm3/h / 220 SCFH

H250 M40R

Variable area flowmeter for oil and gas applications

- For extreme pressure conditions up to 900 barg / 13,000 psig

- Heavy duty design with NACE MR0175 / MR0103 compliant 1.4404 / 316L standard material; optional with NORSOK compliance

- Also available with Hastelloy®, Monel®, Inconel®, 6Mo or titanium

- Explosion-proof (Ex-d) and intrinsically safe (Ex-i) design

H250U M40

Variable area flowmeter for installation in fall pipes

- Unique design for vertical (upside down) installation position

- Accuracy: ±2.5% (acc. to VDI/VDE 3513, sheet 2)

- Up to +200°C / +396°F (with Hastelloy® spring)

- Up to DN50 / 2”

H250H M40

Variable area flowmeter for installation in horizontal pipes

- Unique design for horizontal installation position

- Accuracy: ±2.5% (acc. to VDI/VDE 3513, sheet 2)

- Up to +200°C / +396°F (with Hastelloy® spring)

- Up to DN100 / 4”

Accessories for this product

Applications

Links

Download Center

H250

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver