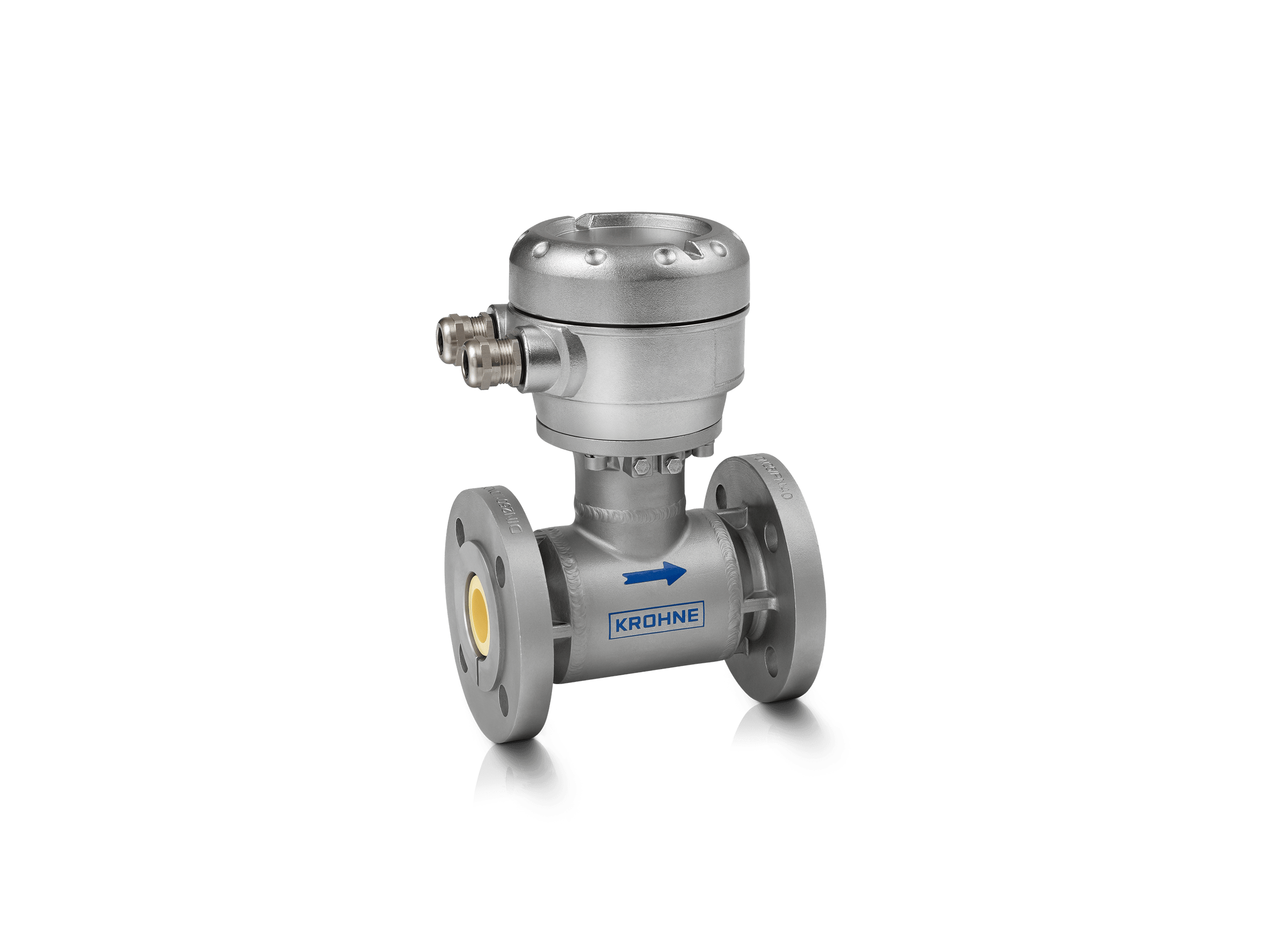

OPTIFLUX 5300

Electromagnetic flowmeter for advanced process and master meter applications

- Highest accuracy (±0.15%), with ceramic tube for aggressive and abrasive liquids (≤70% solid content) up to +180°C / +356°F

- CT: OIML R117, MI-005 etc.

- Flange: DN15…300 / ½…12", max. PN40 / ASME Cl 300; Sandwich: DN2.5...100 / ⅒...4"

- 3 x 4…20 mA, HART®, Modbus, FF, Profibus-PA/DP, PROFINET

OPTIFLUX 5300 C – Compact version with flange

The OPTIFLUX 5300 is an electromagnetic flowmeter (EMF) with a high-tech ceramic measuring tube for very aggressive and abrasive fluids, even with high solid content (up to 70%). The high-end EMF is particularly suited for process applications in the chemical processing industry and the minerals and mining sector. Due to its FDA and EC1935/2004 compliant sensor material, the OPTIFLUX 5300 can also be used for hygienic applications. With a measuring uncertainty of just ±0.15% of measured value (±1 mm/s) it is one of the most accurate electromagnetic flowmeters available in the market. That is why leading metrological institutes use the OPTIFLUX 5300 as their master meter.

Thanks to the unique combination of material properties such as surface hardness and finish, mechanical resistance to corrosion and temperature shock, the OPTIFLUX 5300 outclasses all traditionally lined EMFs. Its patented virtual reference option allows a cost-saving measuring mode without additional grounding rings. The flowmeter comes with flange or as flangeless and space-saving wafer version. Both versions are vacuum-resistant and comply with the Pressure Equipment Directive. The OPTIFLUX 5300 is also approved for use in hazardous areas. It offers various digital communication options. A full on-site verification of the flowmeter without process interruption can be carried out using the OPTICHECK service tool.

Product highlights

- Bi-directional flow measurement over a wide dynamic range (turn down ratio: 1000:1)

- One of the most accurate EMFs in the market: Only ±0.15% / ±1 mm/s error of measured value (MV)

- Transfer standard of international metrological authorities

- Available with patented virtual reference grounding method: no grounding rings needed

- Withstands most aggressive and abrasive fluids

- Extensive flowmeter and process diagnostics (incl. NE 107)

- Fully vacuum-resistant with high-tech ceramic sensor material

- Fused in-place cermet or platinum electrodes

- First EMF with ceramic measuring tube to comply with the Pressure Equipment Directive

- Resistance to corrosion and temperature shocks

- Available as flange or sandwich (wafer) version

- No moving parts, no wear, no pressure loss

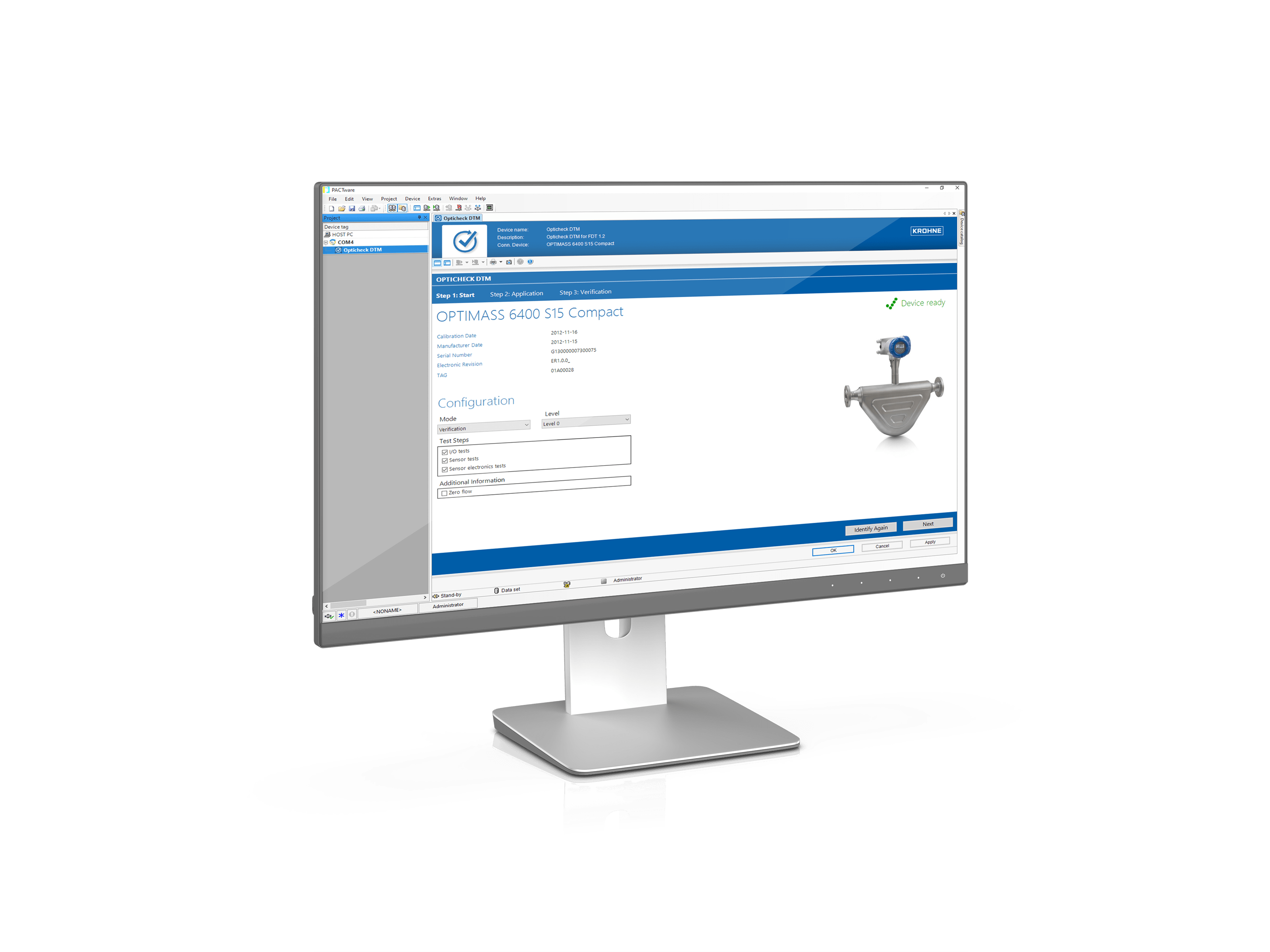

- On-site verification of flowmeter with OPTICHECK service tool

Typical applications

General

- Extremely demanding applications with clean, aggressive or abrasive liquids

- Fiscal metering (custody transfer)

- Applications requiring an EMF with an extremely high rate of accuracy

- For low conductive media (>1 μS/cm)

- Applications with solid content up to 70%

Chemical and other process industries

- Extremely precise volumetric dosing of additives

- Chemical injection

- Inorganic and organic mass production

- Processing of corrosive and aggressive chemicals (acids, alkaline media)

Minerals and mining industry

- Inhomogeneous and abrasive slurries with fine particles (solids content)

- Hydrocyclone feed lines

Food and beverage industry; pharmaceutical industry

- Blending, dosing, batching of conductive liquids

- SIP/CIP applications

Wastewater industry

- Sediment slurries and sludges

- Dosing of coagulants and flocculants

Pulp and paper industry

- Chemically aggressive fibrous products

Others

- Master meter applications in calibration facilities

Accessories for this product

Applications

Related products

Links

Download Center

OPTIFLUX 5000

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver